- Description

- Inquiry

Machine introduction

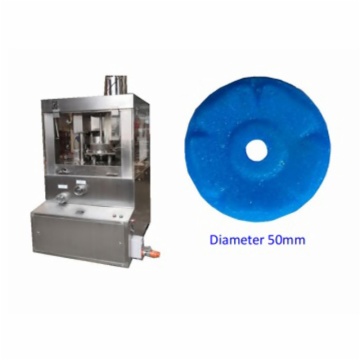

ZPD9 big rotary tablet press is suitable for pressing round/sphere and loop tablets,abnormal shape tablet from granule materials. It is widely applied in pharmacy, foodstuff, chemicals, electronic industries,ect. It cannot be used to press the materials of semi-solid, wet granule, low solubility, hygroscpic features or pure powder without granules. This machine meets the GMP standard.

Working principle and structure features:

1.It is the single press type machine, and installed with 9 sets of punch dies. The punch dies are installed on the working table(simply called as turret), the punches up and down along the rail curve. Pressing process is conducted through the up and down compressing.

2.The technological process for tablet pressing of this machine is continuous feeding, filling moulds, pressing tablet and discharging tablet.

3.The machine is driven by motor. Which drives the speed reducer to rotate the turntable to press tablets by triangle belt.

4.The pinch roller device adopts rolling friction. Its working pressure can be adjusted in accordance with the requirement of tablet to be pressed.

5.The working chamber of the machine is totally enclosed by plexi glass to prevent dust during pressing process. Meanwhile, the whole pressing process can be wholely observed.

6.The thickness and work pressure can be adjusted by indicated direction showed on hand wheels.

7.The rotation speed of turntable can be adjusted by VFD through a konb in electric panel.

8.In Order to keep clean and reliability of electric element, the electric system is ssealed in bottom of machine .

Model

|

ZPD9

|

Max.Pressure

|

350 kn

|

Max.dia of tablet

|

70mm

|

Filling depth

|

45mm

|

Rotating speed of rotation tablet

|

1-15r/min

|

Max.production capacity

|

8100pcs/h

|

Max.thickness

|

20mm

|

Main motor Power

|

7.5kw

|

Net weight

|

2800kg

|

Overall Size(L*W*H)

|

900*900*2200mm

|